PROCESSES

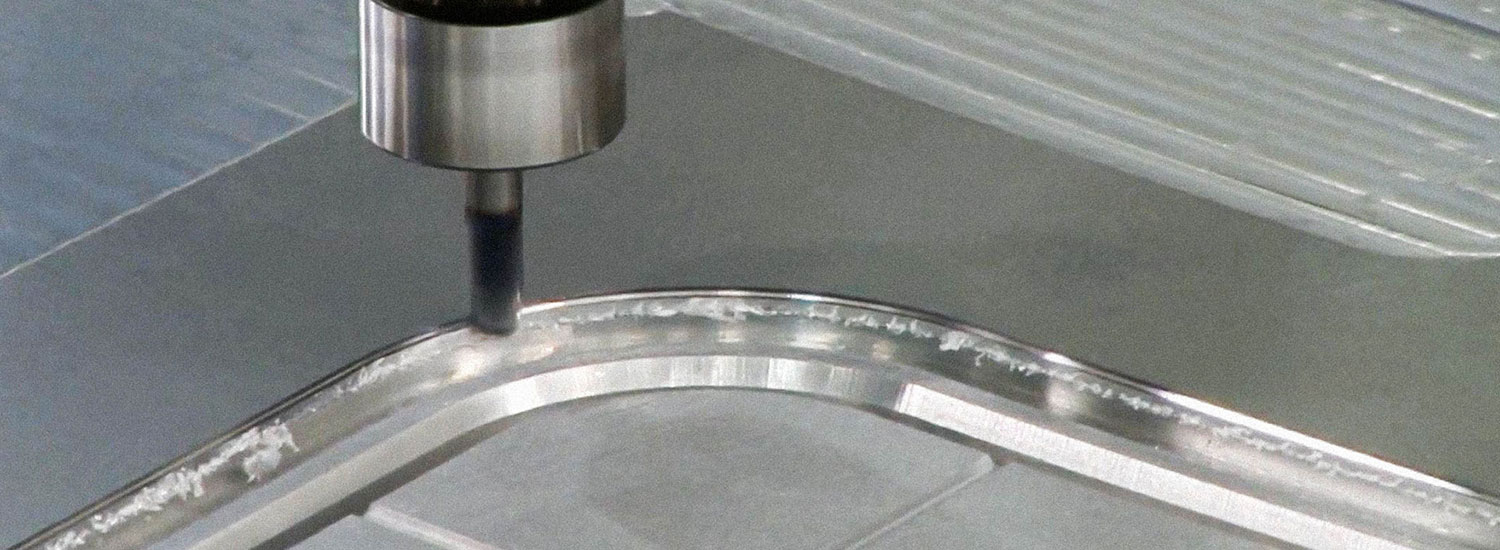

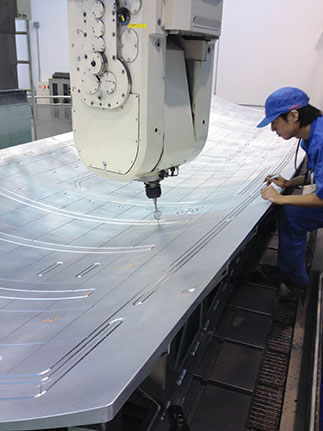

WADA Aircraft Technology primarily utilizes large dimension 5-axis machining centers in the production of a range of complex, high precision jigs and components. Workspace requirements and lead times are significantly reduced through our proprietary integrated production process, which allows us to carry out every required process by CNC machining. In particular, this applies to 5-axis aircraft skin milling, which allows us to avoid chemical milling entirely. This allows for increased precision and quality at a lower cost, shorter work times, a more efficient use of workspace, and a significantly reduced environmental impact.

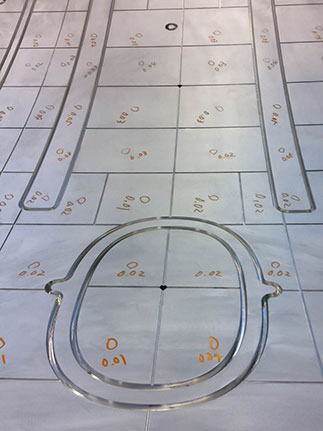

In order to provide products which conform to the high standards that our customers expect, we carry out thorough part inspections during each stage of production. Utilizing on-machine, laser tracker, and CMM inspection processes together with know-how built up through years of experience, we are able to confidently maintain production quality at every stage, guaranteeing end products which match or exceed customer specifications.

|

|

|